50 Years Of #MovingIndia

With technology automating our lives and most part of our jobs (recently, in a Chinese factory 50,000 workers were replaced by 6,000 robots to automate work processes), I’ve always been fascinated by how the past has been & how the future looks. This is when I approached Siemens for a photo-story as I was very excited to cover their journey and how their workplace has evolved in technology driven India over the past 50 years. I started gathering information on factories established in the 60s and that is when I came across Siemens Kalwa Factory setup.

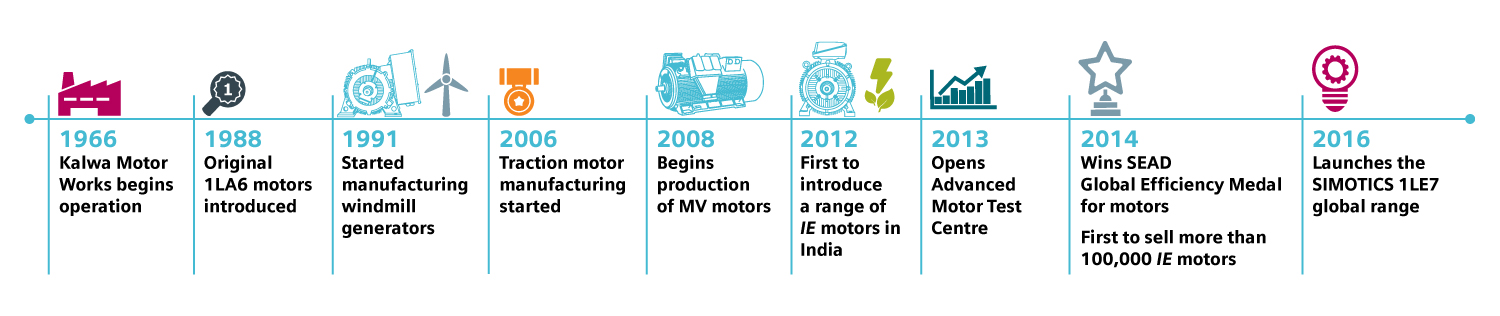

Siemens Factory in Kalwa are celebrating their 50th anniversary this yearand would provide the perfect opportunity to cover how things have changed in these 50 years. Siemens Ltd. is the flagship of the Siemens Group in India & has been a pioneer in motor manufacturing. On digging further into the story, I found that the Siemens Kalwa Motor manufacturing setup is one of the oldest by Siemens Ltd. in India.

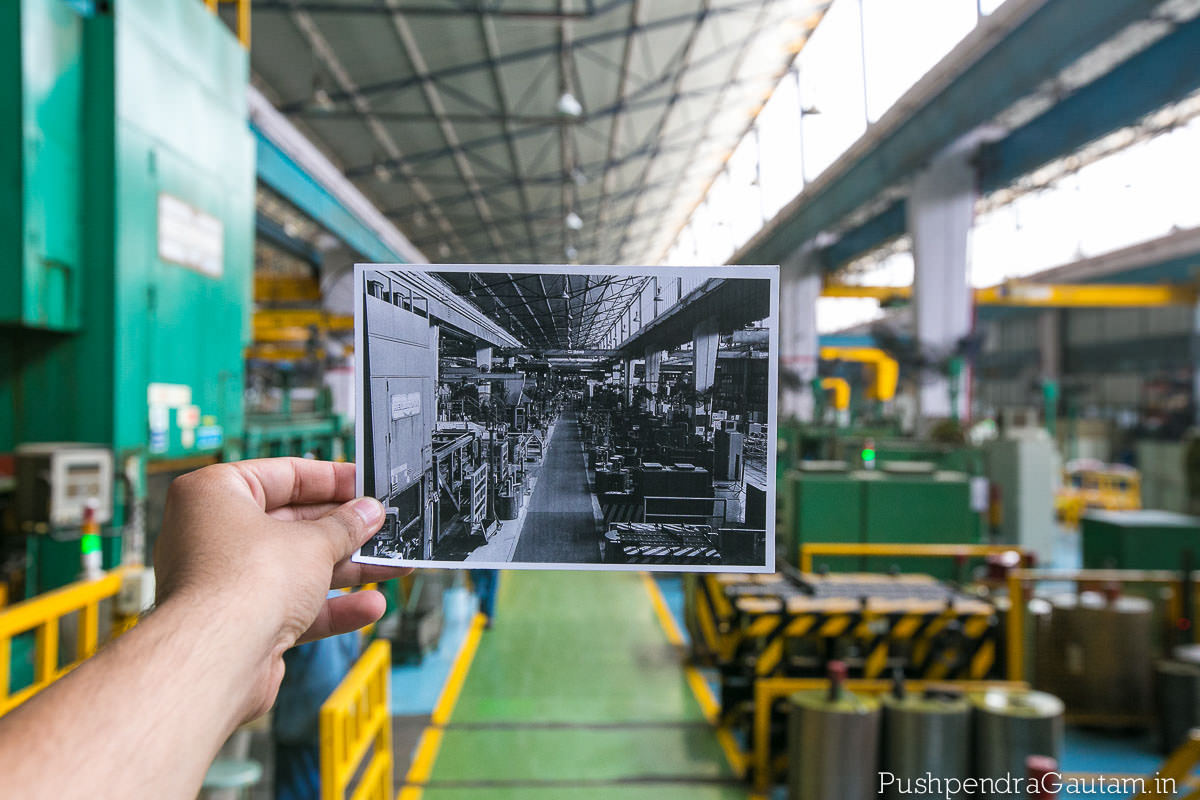

Changes like those from slip ring motors to wind mill generators sound fascinating to a technology lover like me but what would be even better is if I could capture the changes in a single frame. I decided to give it a shot. I flew in from Delhi and it took me just 25 minutes in the morning to reach the factory from the Mumbai Airport (I was glad!). The factory is easily accessible from the city and is located in Kalwa, Mumbai. The permissions for this shoot were taken a day in advance.

This is how things have changed in 50 years

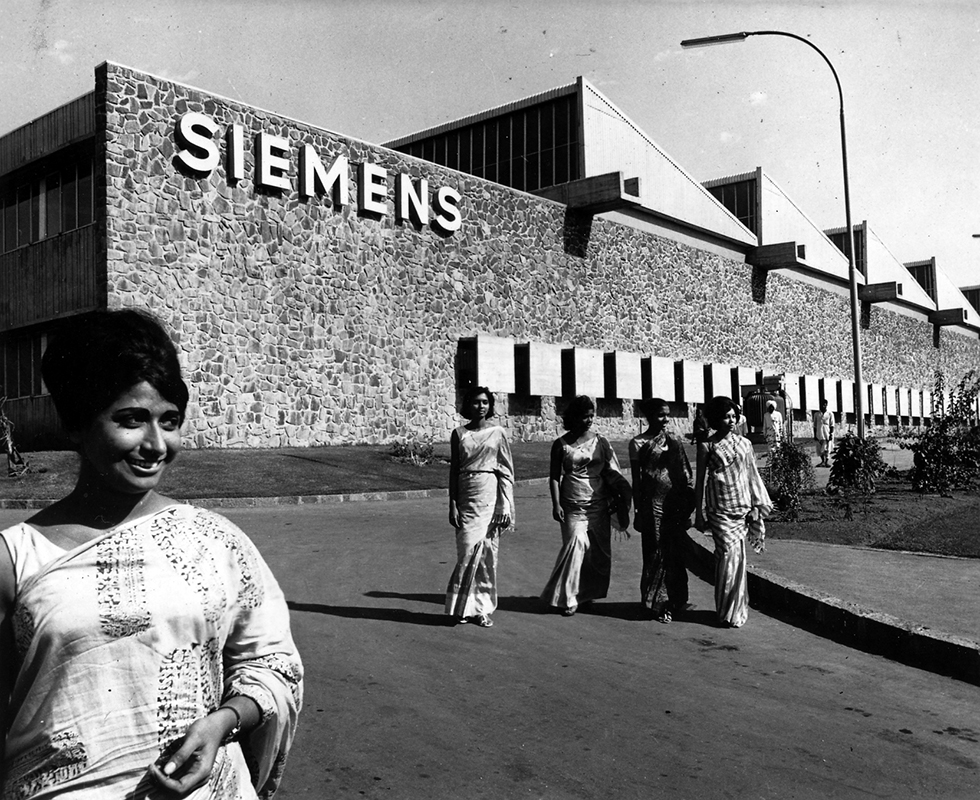

The first stop after I entered was the Siemens facade, which was very interesting in its 1960's shot beautifully with vintage dressed ladies walking in front of the building. This over a period of time had completely changed. While the trees and greenery in the factory area have increased a lot (which is really great), the basic facade structure remains the same today as well.

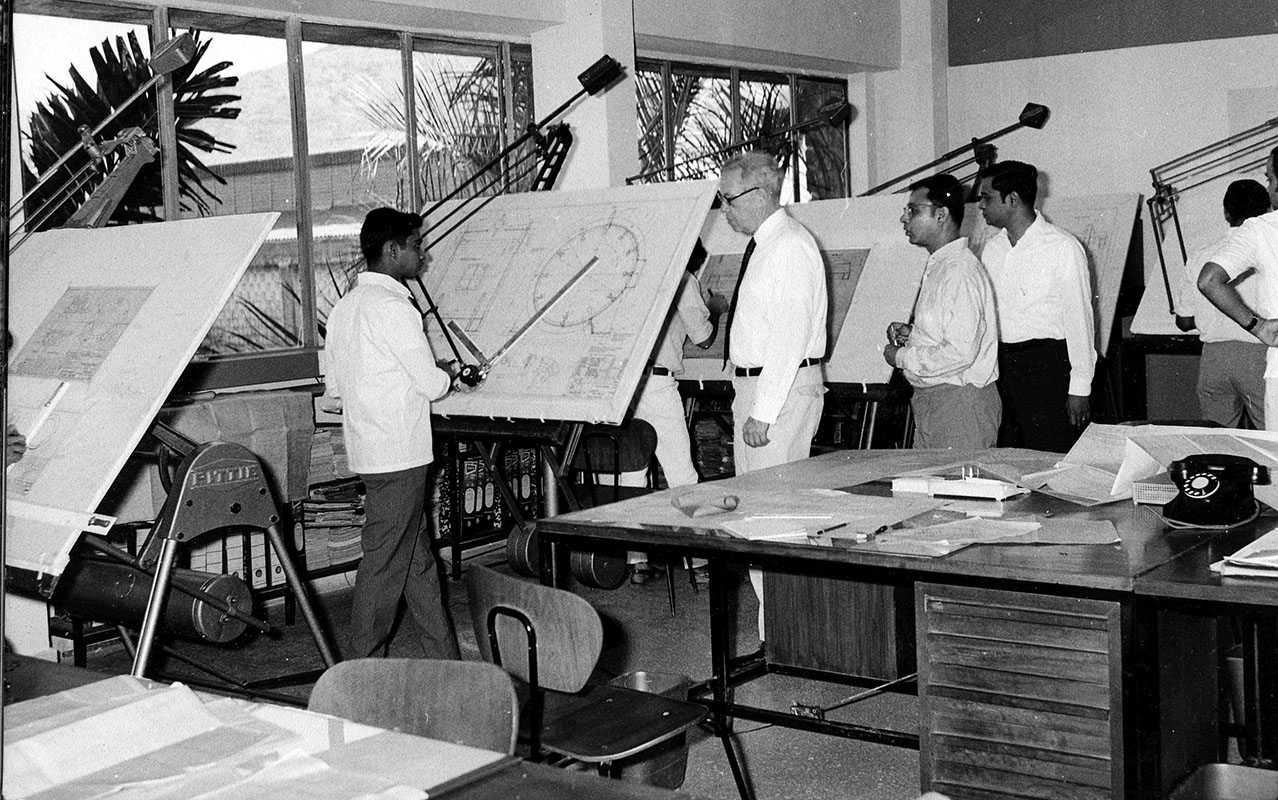

I went inside to see what the factory looks like. I saw that during old days, boards were used to draw plans, which in today's time have been replaced by computers. While there were 2-3 people required previously for a job, the same job has now become easy & accurate with the intervention of technology. This has reduced manual work and the time taken to complete a job.

Automated pulleys and small cranes are being used today making work simpler and faster. Today the work requires less manual labour and takes less time as compared to old days where it used to take hours.

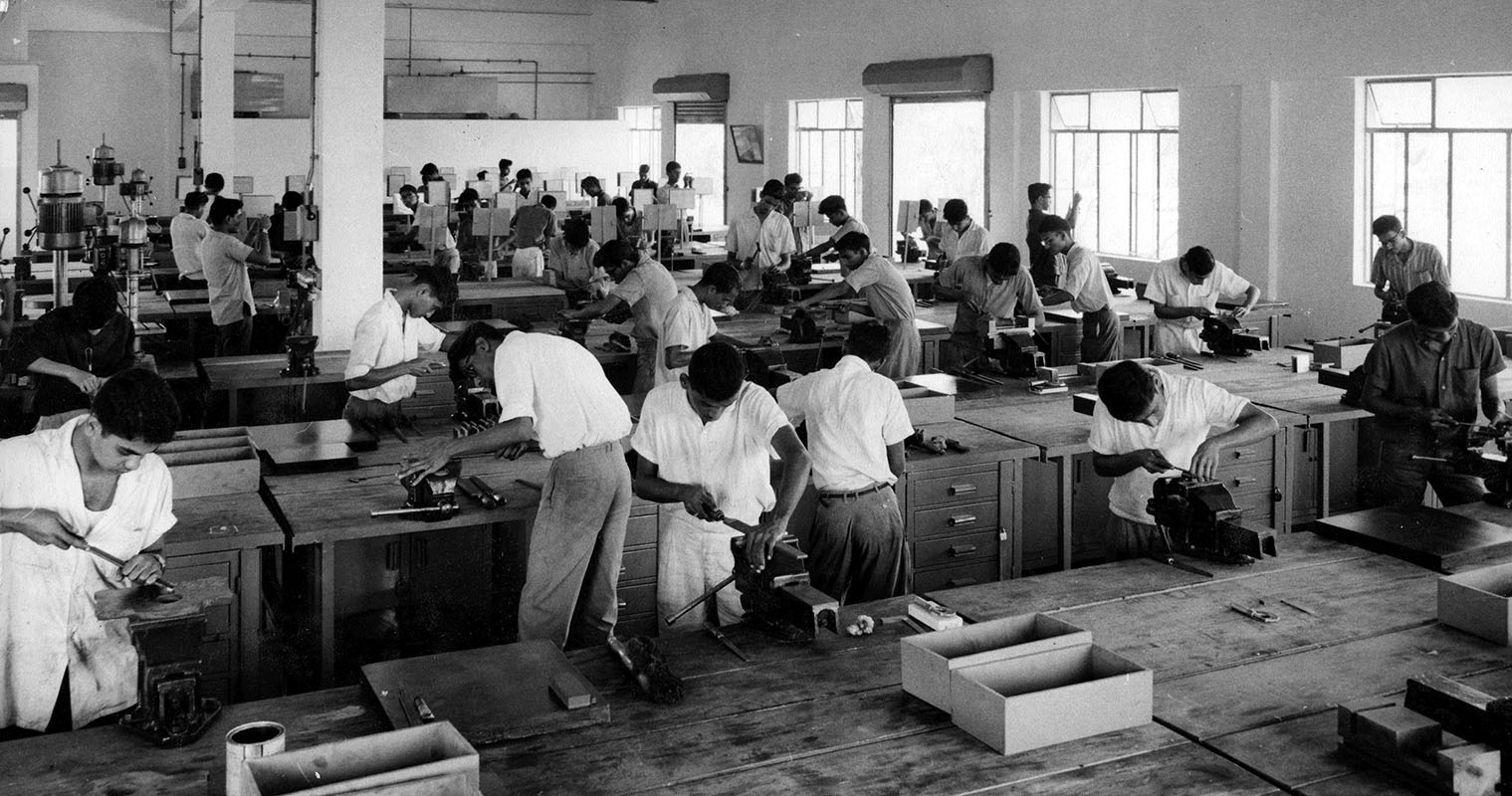

I then moved to the training area. The area has been updated with better environment (light, fans) and advanced tools. What I found commendable was that even in the early years, the factory workers had exemplary working conditions, which have been continuously updated to keep the workers happy.

From all the images I replicated, the one below was one of my favorites. Although in today's scenario the entire machinery (and the environment) has changed, the essence of the process remains the same. The new uniform and the new logo on the machine, however, look undeniably classier.

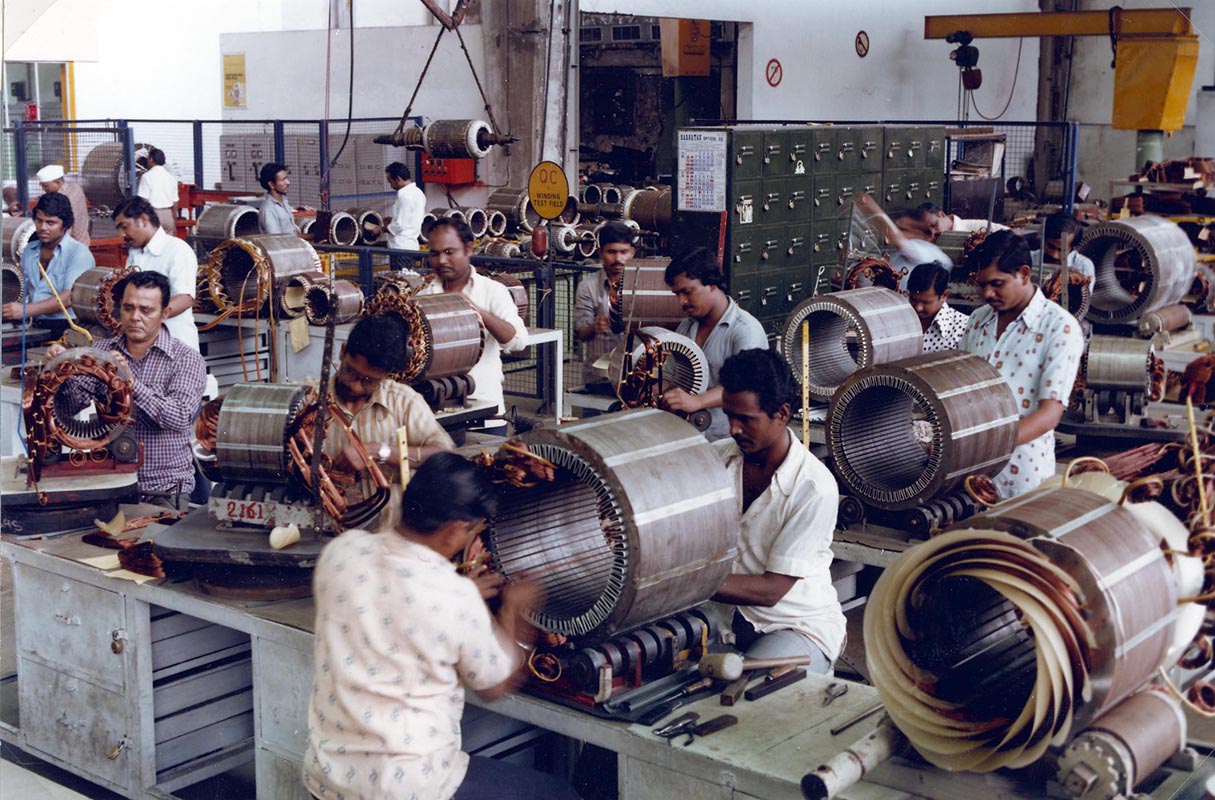

Moving ahead I went to Motor Assembly area. While I’m sure that the machines the workers are working on now are much more advanced than those we see in earlier days, the setup looks similar and bigger.

While they were assembling motors my attention ran across one of the image from the past where the worker was working with his face visible in between the motor's circular area. I moved from one unit to another to get the perfect frame for the shoot.

As technology progressed, the potential hazards in an industry got worse. The updated uniforms of the workers are made of denim.

The denim clothes that the workers wear is lot more resistant to fire than cotton clothes.

The tool kit has drastically changed and looks more organized.

I spoke to the Siemens staff at the industry and found out some interesting facts about the company. They are the leading providers of industry and infrastructure solutions in India. Leveraging the 160-year-long heritage of technology leadership, Siemens offers a solution portfolio consisting of industry-specific applications to optimize the performance of enterprises across the entire value chain.

From manufacturing small size low voltage motors to becoming a unit that presents one of the most diverse portfolio and technology under one roof, Siemens Kalwa Motor Works has been keeping ahead of time, year after year. This is just the beginning, as Siemens Kalwa, backed by 50 years of excellence, looks forward to providing a more energy-efficient future.

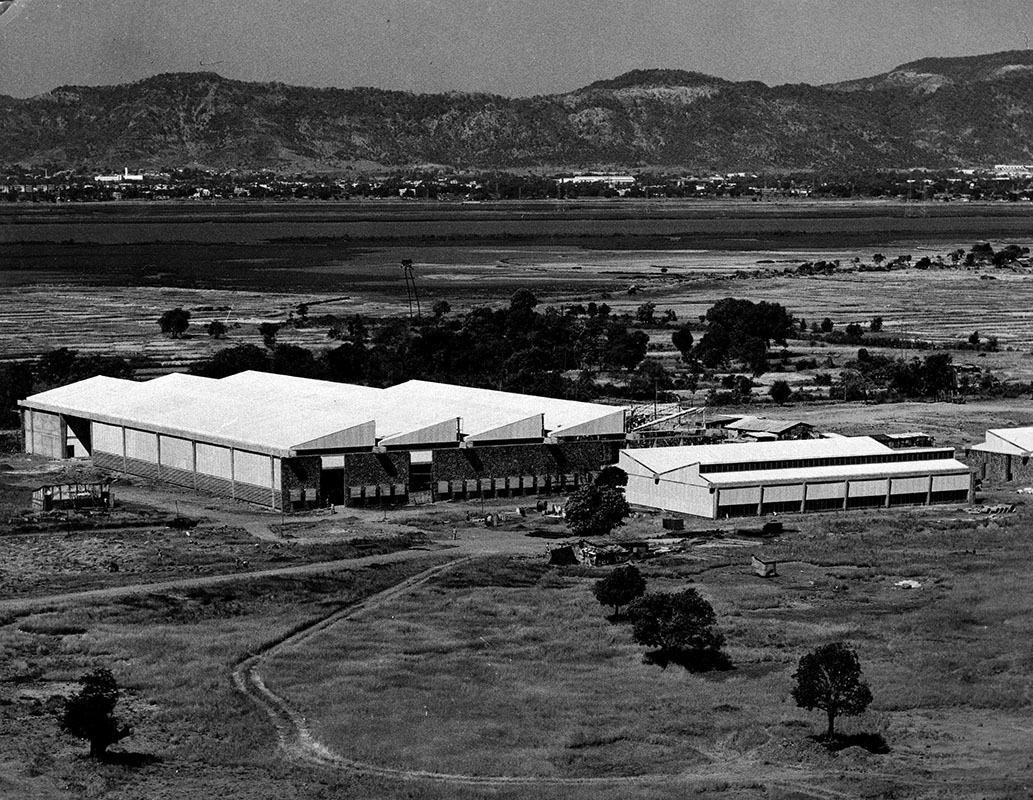

In the end, the picture that I was looking for was a top-shot of the factory's view. 50 years and now, I saw a very different picture. The landscape has totally changed. The view 50 years ago was of a remote location with just one Siemens factory. 50 years later, Siemens has added 4 more factories while the area around it looks completely different & developed. Guess what! It took almost an hour to get to the top and frame this.

Hope everyone loved this post. Please do comment if you have questions, suggestions or feedback. Happy to respond.